Lime rendering is a traditional building technique that not only enhances the aesthetic appeal of structures but also offers numerous practical benefits. This guide explores the definition of lime rendering, its widespread applications, and its advantages in comparison to other materials. It details the application process, the necessary tools, and the types of surfaces that are suitable for lime render. Additionally, common issues and maintenance tips are addressed, emphasizing the environmentally friendly aspects of lime rendering. This comprehensive guide serves to provide valuable insights into the enduring charm and functionality of lime rendering, catering to homeowners, builders, and DIY enthusiasts alike.

What Is Lime Rendering?

Lime rendering is a time-honoured plastering technique that employs lime-based materials, including lime render and lime plaster, recognised for their breathable properties and exceptional moisture absorption capabilities.

This method has been utilised in a variety of historical contexts, such as ancient Egypt and Pompeii, and continues to be a favoured option for renovation projects due to its environmentally sustainable characteristics and its capacity to preserve the structural integrity of buildings.

Lime render can be applied to both new and existing structures, rendering it a versatile solution for contemporary construction and restoration efforts.

Why Is Lime Rendering Used?

Lime rendering is extensively used in construction and renovation projects owing to its numerous advantages compared to conventional materials such as gypsum and cement. Its breathable characteristics enable walls, often made from building materials like brick and stone, to effectively regulate moisture, thereby preventing damp-related issues that could jeopardise structural integrity.

Furthermore, lime render is environmentally sustainable and contributes to the preservation of historic buildings, which positions it as a preferred option for traditional building methods.

What Are The Benefits Of Lime Rendering?

The benefits of lime rendering include its capacity to absorb moisture, which helps prevent issues such as dampness and mould, thereby preserving the structural integrity of buildings. Lime render, made from calcium carbonate and other lime-based materials, is regarded as an environmentally friendly option due to its natural composition and lower carbon footprint in comparison to traditional cement and plaster of Paris.

Lime rendering enhances durability while providing exceptional moisture regulation through its permeable properties. This characteristic allows the material to absorb excess moisture during wet conditions and release it in drier atmospheres, effectively managing indoor humidity levels.

Numerous case studies, such as those conducted by Cornish Lime and ASBP, have shown that buildings treated with lime render experience significantly reduced instances of mould and bacterial growth, thereby ensuring a healthier living environment.

Furthermore, sustainability is a critical advantage, as lime is often sourced from local materials, which minimises transport emissions. Lime render is also compatible with various building materials such as brick, stone, and timber, allowing for versatile applications in both restoration and new construction projects.

Ultimately, selecting lime rendering, which incorporates both hydraulic lime and non-hydraulic lime options, not only aligns with modern ecological practices but also contributes to the longevity and stability of architectural structures.

What Are The Different Types Of Lime Render?

There are several types of lime render, primarily categorised into non-hydraulic lime and hydraulic lime, each serving distinct purposes in traditional construction and contemporary renovations. Non-hydraulic lime is commonly utilised for interior applications, whereas hydraulic lime offers increased strength and water resistance, rendering it suitable for external surfaces. Lime render can also be combined with other materials, such as gypsum plaster, to achieve specific finishes.

The selection of lime render significantly influences both the durability and aesthetic quality of structures. A thorough understanding of the distinctions between these types is essential for ensuring appropriate application in their respective environments.

For example, non-hydraulic lime, known for its general principles of application, is generally suitable for dry indoor settings due to its breathability and flexibility, making it an excellent choice for historic restoration projects where moisture management is paramount. In contrast, hydraulic lime, which features faster setting times and enhanced resistance to dampness, is ideal for areas exposed to harsh weather conditions, such as the external walls of heritage buildings or contemporary homes.

- Non-Hydraulic Lime: Best suited for interior use, allowing for movement and breathability.

- Hydraulic Lime: Optimal for exterior applications, maximising strength against moisture.

In comparison to gypsum plaster, lime render offers superior moisture control and minimises the risk of cracking under fluctuating humidity conditions. By carefully selecting between these materials, builders can significantly enhance both the performance and longevity of their projects.

How Is Lime Rendering Applied?

The application of lime rendering entails a detailed plastering process that comprises multiple layers: the scratch coat, float coat, and finishing coat. This plastering process ensures durability and aesthetics, with each layer serving a distinct purpose, starting with the scratch coat, which provides a key for the subsequent layers.

This is followed by the float coat, designed for levelling, and concludes with the finishing coat, which enhances both aesthetics and durability.

Employing proper application techniques is crucial for attaining a long-lasting and effective lime render finish.

What Tools And Materials Are Needed For Lime Rendering?

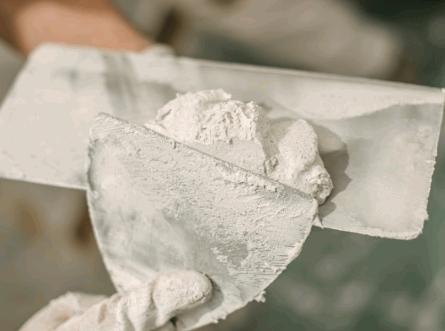

To effectively implement lime rendering, specific tools and materials are essential, including a range of plastering tools such as trowels, hawks, and mixers. Lime renders typically consist of a blend of coarse aggregate and fine aggregate that enhance both the texture and workability of the final product, alongside the primary ingredient of lime, which may be either non-hydraulic or hydraulic.

For a successful lime rendering process, it is imperative to assemble the appropriate tools and materials. Below is a list of the necessary items:

- Trowels: Used for smoothing and applying the render.

- Hawks: Useful for holding the lime render within easy reach during application.

- Mixers: Crucial for achieving a uniform consistency when combining aggregates and lime.

- Float: A tool that assists in finishing the surface to the desired texture.

- Coarse Aggregates: These provide strength and bulk to the render.

- Fine Aggregates: Important for achieving a smooth surface and ensuring uniform application.

- Water: Essential for the mixing process and for maintaining the workability of lime.

A comprehensive understanding of the role of each tool and material will not only streamline the application process but also significantly enhance the quality and longevity of the completed work.

What Is The Process Of Lime Rendering?

The process of lime rendering commences with thorough surface preparation, ensuring that the substrate is clean and suitable for application. Subsequently, a scratch coat is applied to create a textured surface that facilitates adhesion.

Following this, a float coat is introduced to achieve a level surface, ultimately culminating in the application of the finish coat, which imparts the desired aesthetic and protective qualities.

Ahead of any application, it is imperative to inspect the surface for existing contaminants, such as dust, grease, or loose materials. This surface preparation is foundational to a successful application, as it directly influences the bond between the lime rendering and the substrate.

After the surface has been adequately prepared, the scratch coat is applied with precision. This initial layer establishes a rough texture that enhances the bond with subsequent coats. Once the scratch coat has cured, the float coat is applied, providing a smoother surface that addresses any imperfections.

The final stage involves the application of the finish coat, which not only enhances visual appeal but also adds a layer of resilience against environmental factors.

What Surfaces Are Suitable For Lime Rendering?

Lime rendering is suitable for a diverse range of surfaces, particularly in traditional buildings and renovation projects where moisture regulation is essential for preserving structural integrity. Its use of breathable material ensures compatibility with substrates like brick, stone, and cob.

It can be applied to various substrates, including brick, stone, and cob, provided that these materials are compatible with the breathable properties of lime render.

Learn about: How To Lime Plaster A Ceiling

What Are The Common Issues With Lime Rendering?

Lime rendering presents numerous advantages; however, several common issues may occur, including cracking, blistering, and efflorescence. These problems can negatively impact both the structural integrity and aesthetic appearance of the surface.

It is crucial to understand these potential challenges to ensure the longevity and effectiveness of lime render applications.

How To Prevent Cracking In Lime Render?

Preventing cracking in lime render necessitates meticulous attention to moisture control throughout the application and curing processes. Employing proper application techniques, such as adhering to the appropriate thickness for each coat and ensuring sufficient drying times, is essential to mitigate the risk of cracks in the final surface.

Understanding the environmental conditions during application can significantly impact the efficacy of lime render. Moisture control is paramount; thus, it is advisable to avoid application during extreme temperatures or when heavy rainfall is predicted to preserve the integrity of the render.

Additional strategies include:

- Utilising compatible substrates to ensure proper adhesion, as the use of incompatible materials can induce stress and cracking.

- Implementing a multi-coat approach, allows each layer to partially cure before the application of subsequent coats, thereby promoting moisture balance.

- Employing protective coverings during the curing stage to shield freshly applied render from direct sunlight and wind, can lead to rapid drying and potential cracking.

By adopting these methods, individuals can enhance the durability and aesthetic quality of the lime render, resulting in a more resilient finish that endures over time.

How To Fix Blistering In Lime Render?

Blistering in the lime render is frequently the result of trapped moisture or improper application techniques, often seen with materials like plaster of Paris. Addressing this issue necessitates meticulous repair methods, which may involve the removal of the affected areas, ensuring appropriate surface preparation, and correctly reapplying the lime render.

A thorough understanding of the underlying causes of blistering is crucial for effective remediation. Typically, moisture retention occurs due to insufficient drying or environmental factors, such as damp issues, while improper application techniques—such as incorrect mixing or layering—can exacerbate the issue.

To prevent further occurrences, effective moisture management is essential. Consider the following strategies:

- Ensure adequate ventilation during and after the application.

- Utilise moisture meters to monitor levels prior to application.

- Select an appropriate time for application, avoiding damp conditions.

Implementing these techniques not only facilitates immediate repair but also significantly enhances the longevity of the lime render, making it essential for anyone aiming to maintain the integrity of their surfaces.

How To Deal With Efflorescence In Lime Render?

Efflorescence, characterised by the presence of white powdery deposits on the surface of lime render, typically arises from excessive moisture and soluble salts like Calcium Carbonate within the material. To effectively address this issue, it is imperative to implement robust moisture management strategies in conjunction with cleaning techniques aimed at removing the visible salt deposits without causing damage to the underlying render.

The primary factors contributing to efflorescence include groundwater presence, inadequate drainage systems, and rising damp conditions. These circumstances facilitate moisture migration through the material, carrying dissolved salts that subsequently crystallise on the surface upon evaporation.

To effectively mitigate occurrences of efflorescence, it is advisable to consider a combination of the following strategies:

- Improved drainage: Ensure that appropriate drainage systems are in place to redirect water away from structures.

- Waterproofing: Apply waterproof membranes or sealants to prevent moisture ingress.

- Regular maintenance: Schedule routine inspections and maintenance to identify and address potential issues before they escalate.

Cleaning methods for efflorescence generally involve using a brush to gently remove the powder, followed by washing the area with water. In instances of significant buildup, a mixture of vinegar and water may prove effective in dissolving the salt deposits.

However, it is crucial to test any cleaning solution on a small, inconspicuous area first to avoid damaging the lime render.

How To Maintain Lime Render?

Maintaining lime render requires regular cleaning and inspections to ensure both its longevity and aesthetic appeal. Employing gentle cleaning methods, instead of harsh chemicals, and applying protective coatings when necessary are effective practices for preserving the integrity and appearance of lime render over time.

To manage the upkeep of this natural material effectively, it is imperative to adopt a structured approach that encompasses various maintenance practices. Regular inspection routines should be implemented to identify issues such as cracks or discolouration at an early stage, allowing for prompt intervention. Cleaners should prioritise milder solutions, such as water mixed with biodegradable soaps, to avoid damaging the surface.

Furthermore, it is advisable to:

- Conduct visual checks for structural integrity at least twice a year.

- Clean the surface using soft brushes or low-pressure washers to dislodge debris without harming the render.

- Apply protective coatings every few years to shield against moisture and environmental elements.

By adhering to these practices, homeowners can maintain both the aesthetic and functional aspects of lime render, ensuring that it remains an attractive feature of their property.

Is Lime Rendering Environmentally Friendly?

Lime rendering is often acknowledged as an environmentally friendly option in construction due to its natural ingredients like Calcium Hydroxide and lower carbon footprint compared to conventional materials such as cement and gypsum.

The sustainable properties of lime rendering not only enhance aesthetic appeal but also contribute significantly to healthier indoor environments and align with the principles of green building. When comparing lime rendering to more traditional materials, it becomes evident that lime promotes improved air quality by regulating humidity levels and absorbing carbon dioxide over time. In contrast to synthetic alternatives, lime is biodegradable and poses minimal environmental hazards, making it a preferable choice for environmentally conscious builders.

The key benefits of lime rendering can be summarised as follows:

- Utilisation of natural ingredients leads to a low ecological impact.

- Enhancement of indoor air quality.

- Biodegradable nature, thereby minimising waste concerns.

- Carbon absorption capabilities that improve the overall carbon footprint.

In conclusion, selecting lime rendering is not merely an aesthetic decision; it represents a deliberate commitment to sustainability.