Lime plaster is a traditional material that has proven its durability and is valued for its versatility and aesthetic qualities, often used in home renovation projects. As one delves into the realm of skim coating, questions may arise regarding the role of lime plaster and other modern materials within this context. This article aims to clarify the definition of lime plaster, outline the skim coating process, and evaluate the effectiveness of lime plaster and other plastering materials for this application. Additionally, it will examine the various types of lime plaster, including natural hydraulic lime and non-hydraulic lime, their advantages, and how they compare to alternative materials like gypsum. Regardless of whether you are a do-it-yourself enthusiast or a seasoned professional plasterer, this article will provide valuable insights to enhance your renovation projects.

What Is Lime Plaster?

Lime plaster is a traditional building material composed primarily of lime, water, and aggregates, often used in both historical and modern properties. It is recognised for its breathable properties and effective moisture management, rendering it an excellent choice for renovation projects in both modern and historical properties, helping to maintain the architectural integrity of such buildings.

This versatile material has been utilised for centuries, with origins tracing back to ancient civilisations in Egypt and Italy, including the ancient lime plasters used in Pompeii, and it continues to be a preferred method for interior and exterior plastering in the UK today.

Its composition generally includes calcium carbonate, calcium hydroxide, and various aggregates, such as pumice, all of which enhance its carbonisation effectiveness and durability.

Check out: What Is Lime Rendering

What Is Skim Coating?

Skim coating is a plastering technique that involves the application of a thin layer of plaster, such as lime plaster or gypsum, over existing surfaces to achieve a smooth and even finish. This process not only enhances the aesthetic appeal of walls and ceilings but also contributes to the overall improvement of interior environments by providing a breathable surface.

This characteristic is particularly beneficial in mitigating damp issues and maintaining the architectural integrity, making skim coating an ideal choice for renovation projects in historic buildings.

Can You Skim Coat With Lime Plaster?

Yes, it is possible to skim coat using lime plaster, which is often preferred for its breathable properties and effective moisture management, particularly in heritage properties. This makes it an excellent choice for various renovation projects. Skim coating with lime plaster facilitates the creation of a smooth finish, which is essential for enhancing both the aesthetic value and functionality of walls in modern and historic properties, and is well-suited for both internal and external work.

The use of lime plaster offers numerous advantages that extend beyond aesthetics and aligns with sustainable building practices. Its breathability allows for the natural movement of moisture, thereby preventing issues such as mould and dampness while contributing to a healthier indoor climate for occupants and preserving the integrity of traditional materials. When applied correctly, lime plaster can adapt to varying humidity levels, making it suitable for applications in bathrooms, kitchens, and areas prone to moisture accumulation, addressing common damp problems.

- Practical Considerations: It is essential to ensure that the substrates are clean and sound prior to application.

- Techniques: A two to three-coat system is recommended to achieve optimal thickness and durability.

Given these properties, lime plaster is particularly advantageous for restoration work on historic buildings, as it is compatible with traditional materials and aids in preserving the integrity of older structures while providing modern functionality and addressing environmental conditions.

What Are The Benefits Of Using Lime Plaster For Skim Coating?

Utilising lime plaster for skim coating presents numerous advantages, primarily due to its breathable nature, which allows walls to 'breathe.' This characteristic significantly reduces moisture accumulation and potential damp issues in both modern and historic properties. Such a feature is particularly beneficial in renovation projects, as it aids in preserving the integrity and longevity of traditional materials, thereby maintaining the architectural character of the building and its historical properties.

In addition to its moisture-regulating capabilities, lime plaster possesses excellent insulation properties, contributing to a more energy-efficient environment. Properties treated with lime plaster may experience reduced heating costs, which aligns well with contemporary building standards that prioritise sustainability and energy efficiency, making it a preferred choice for construction projects.

Lime plaster is recognised for its remarkable durability; its natural resistance to cracking and wear enables it to outperform conventional materials over time, making it ideal for both renovation and new construction projects.

- For instance, a historic structure restored with lime plaster not only enhances its aesthetic appeal but also improves its structural integrity.

- The material's flexibility allows it to accommodate minor shifts in the building without compromising the surface integrity.

- Furthermore, lime plaster is an ideal choice for historic restorations, as it can replicate the original finishes utilised in period homes, thereby retaining their charm while ensuring compliance with modern building regulations, and maintaining the architectural integrity of the property.

What Are The Steps To Skim Coat With Lime Plaster?

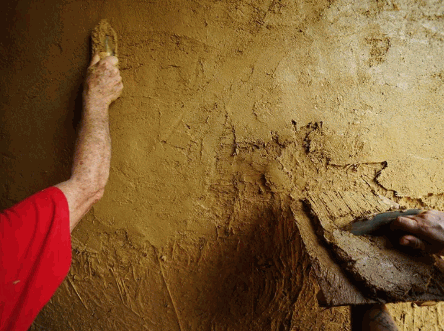

The process of skimming with lime plaster entails meticulous surface preparation, careful application of the plaster, and achieving a smooth finish, all of which are vital for the success of a renovation project and overall building maintenance. Initially, it is essential to clean the surface thoroughly and repair any damaged areas to ensure proper adhesion and the durability of the lime plaster, which may involve some trial and error. Following this, the lime plaster should be mixed to the appropriate consistency for optimal application, as recommended by brands like Cornish Lime or Ty-Mawr.

Once any imperfections have been addressed, it is critical to allow the surface to dry sufficiently before beginning the plastering process. This step is necessary to prevent moisture from interfering with adhesion.

Next, the mixing of the lime plaster should be conducted in accordance with the manufacturer's instructions, resulting in a creamy texture akin to thick yoghurt, which facilitates ease of application, ensuring the plaster coats are smooth and consistent. It is advisable to utilise clean tools during the mixing process to prevent contamination, particularly when dealing with sensitive renovation work.

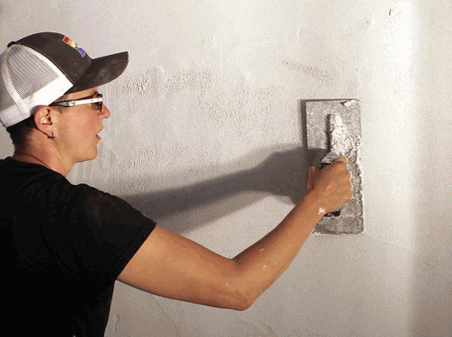

In the application phase, a stainless steel trowel should be employed to achieve a smoother finish, applying the plaster in thin layers, ensuring that each layer has the proper time to bond and dry. This technique not only promotes breathability of the base but also minimises the risk of cracking, ensuring long-lasting results. It is recommended to work in sections to maintain consistency and avoid premature drying of the plaster.

- Ensure even pressure is applied to the trowel for uniform coverage.

- Take the time to feather out edges to blend layers seamlessly.

- Once the surface is tacky but not completely dry, utilise a sponge or float to refine the finish.

By employing these techniques, individuals can attain a professional-looking surface that significantly enhances the overall aesthetic and structural integrity of the building.

What Tools Are Needed For Skim Coating With Lime Plaster?

To successfully apply a skim coat with lime plaster, several essential tools are required, including trowels, hawks, and mixers, all of which are necessary for achieving a smooth and even finish, and addressing different working conditions. These tools assist plasterers in both the preparation and application of lime plaster, ensuring that the final result meets the aesthetic and functional requirements of renovation projects and maintaining the architectural character of the property.

Understanding the specific function of each tool is crucial for enhancing the overall quality and efficiency of the skim coating process, often requiring a trial-and-error approach. The trowel is a fundamental implement essential for spreading and shaping the plaster smoothly onto surfaces, ensuring an even application. A hawk allows artisans to hold a generous amount of plaster for easy retrieval, significantly minimising the time spent bending and reaching, thus improving efficiency. A reliable mixer is critical for ensuring a consistent and workable plaster mixture, which helps to prevent issues such as cracking or unevenness in the final application, and ensures that the lime, water, and aggregates are properly combined.

- Trowels: Used for applying and finishing the plaster.

- Hawks: Carry and supply plaster to the trowel.

- Mixers: Combine lime, sand, and water to achieve the appropriate consistency.

Proper utilisation of these tools not only maximises efficiency but also enhances the long-term durability and appearance of plastered surfaces, ensuring that the restoration work meets high standards.

What Are The Different Types Of Lime Plaster?

Lime plaster is available in several varieties, including hydraulic lime plaster, non-hydraulic lime plaster, and lime putty plaster, each type serving specific construction needs. Each type possesses distinct properties and applications that cater to different renovation requirements and environmental conditions, ensuring that the right material is used for the right project.

A thorough understanding of these types is essential for selecting the appropriate plaster for specific projects, particularly when taking into account factors such as moisture management, the preservation of historic properties, and the environmental conditions of the site.

Hydraulic Lime Plaster

Hydraulic lime plaster is a specialised type of lime plaster that solidifies through a chemical reaction with water, making it particularly suitable for construction and renovation projects in areas subject to moisture exposure, such as bathrooms and kitchens. This plaster is recognised for its strength and durability, allowing it to perform effectively in both interior and exterior settings, thus serving as an ideal solution for safeguarding buildings against damp-related issues and maintaining the structural integrity of historical and modern properties.

A notable characteristic of hydraulic lime plaster is its breathability, which allows it to absorb and release moisture. This quality helps prevent the growth of mould and mildew. Additionally, hydraulic lime plaster exhibits greater flexibility compared to traditional cement plaster, thereby minimising the risk of cracking due to structural movement. Hydraulic lime, such as that from St Astier or Ty-Mawr, has been used for past centuries in various historic structures.

The advantages of utilising hydraulic lime plaster include its environmentally friendly composition, often comprising Calcium Carbonate and Calcium Hydroxide, and its superior thermal performance, which enhances energy efficiency in structures. Key benefits include:

- Suitability for historic buildings that require preservation

- Common application in construction projects situated in humid climates

- Ease of application, as it can be applied by hand or machine

Given these attributes, hydraulic lime plaster is especially favoured in renovation projects where moisture resistance is critical, ensuring the longevity and stability of the structures involved. Notably, it has been employed in various regions, including Italy, Egypt, and the UK, for its durability and adaptability.

Non-Hydraulic Lime Plaster

Non-hydraulic lime plaster is a variant that utilises carbonisation to achieve hardness, requiring exposure to air. This process results in a highly breathable finish, making it particularly suitable for renovation projects that focus on historic properties. Typically, this type of plaster includes components like Calcium Oxide and Calcium Hydroxide.

This type of plaster provides both flexibility and compatibility with traditional materials, rendering it a preferred choice for projects aimed at preserving architectural integrity. Its breathability is essential when working with older structures, as it facilitates moisture escape while concurrently preventing damage caused by trapped humidity. Examples include the restoration of structures from Pompeii to traditional Farm buildings.

- This characteristic is especially advantageous in regions experiencing fluctuating temperatures and humidity levels.

- The natural composition of the plaster aligns effectively with historic building materials, such as stone and brick, thereby enhancing both aesthetic appeal and structural integrity. Brands like Cornish Lime and Ty-Mawr offer products especially suited for such purposes.

- Restorers frequently favour this lime plaster due to its ease of application and adaptability to various finishes, enabling a range of textures and appearances that can seamlessly work together with the original architecture. In regions like the UK, it is often the plaster of choice for cottages and historic sites.

In conclusion, the incorporation of non-hydraulic lime plaster into renovation efforts serves to preserve the character of historic buildings while promoting longevity and sustainability.

Lime Putty Plaster

Lime putty plaster is a type of lime plaster produced by mixing aged lime with water, resulting in a smooth and malleable paste that can be readily applied and shaped during the finishing process. This plaster is particularly beneficial for renovation projects due to its excellent adhesion to various surfaces and its remarkable durability. It involves traditional methods that have been in use since WW1 and WW2.

Plus its strength, lime putty plaster possesses several key properties that render it a preferred choice among builders and preservationists. A notable advantage is its breathability, which allows moisture to escape from walls, thereby mitigating issues such as mould and decay. Furthermore, its compatibility with traditional building methods makes it especially suitable for the restoration of historical structures.

- Ease of Application: The smooth consistency facilitates straightforward application using a trowel or brush. It can be applied over plasterboard for a traditional finish.

- Versatile Finishing Options: Lime putty plaster can be polished, textured, or coloured, meeting a wide range of aesthetic requirements.

- Eco-Friendly: Composed of natural materials, it supports sustainable building practices.

This material significantly enhances both the longevity and visual appeal of modern renovations and historical restorations.

What Are The Pros And Cons Of Using Lime Plaster For Skim Coating?

Lime plaster for skim coating offers both advantages and disadvantages that warrant careful consideration prior to its application in renovation projects.

On one hand, lime plaster is highly breathable and effectively manages moisture, making it particularly suitable for historic properties. Conversely, it necessitates specific working conditions and techniques, which may present challenges for plasterers.

Pros:

The utilisation of lime plaster offers numerous advantages, particularly its breathability, which effectively mitigates moisture accumulation. This characteristic makes it especially suitable for renovation projects in historical properties where the preservation of structural integrity is of paramount importance. Furthermore, lime plaster is a non-toxic material that contributes to healthier indoor environments.

This quality positions lime plaster as an optimal choice for individuals seeking to improve both the aesthetic appeal and air quality of their living spaces. Lime plaster serves as a natural solution for moisture control by permitting walls to breathe, thereby preventing complications such as mould growth and unwanted dampness. Its inherent flexibility allows it to adapt to fluctuations in temperature and humidity without cracking, making it appropriate for diverse climates and conditions.

- The alkalinity of lime plaster also serves to deter pests and bacteria, fostering a healthier living environment.

- Its ecological properties affirm that lime plaster is a sustainable option in contemporary construction, offering a reduced carbon footprint in comparison to synthetic materials.

- The aesthetic charm of lime plaster lies in its distinctive texture and finish, which accommodates a range of decorative applications.

Incorporating lime plaster into renovation endeavours not only preserves the historical significance of a property but also enhances comfort and sustainability, rendering it a prudent investment for both present and future considerations.

Cons:

Despite its advantages, the use of lime plaster presents certain challenges, particularly regarding application and drying times, which can complicate renovation efforts. Addressing these challenges necessitates skilled plasterers who are well-versed in lime plaster techniques to ensure successful results.

To effectively manage these issues, it is essential to recognise that lime plaster requires a high degree of craftsmanship and patience. The application process can be labour-intensive, involving multiple layers and significant experience to achieve a durable finish. Moreover, the drying times can vary considerably, often requiring extended periods before the plaster is fully cured. This prolonged timeline may disrupt project schedules and lead to increased labour costs.

Maintenance considerations are also critical; lime plaster may necessitate periodic reapplication or repair, particularly in environments exposed to moisture or movement. The interplay of these factors underscores the importance of a well-informed approach when selecting lime plaster for any renovation project.

How Does Lime Plaster Compare To Other Skim Coating Materials?

From ancient civilizations like Egypt and Pompeii to modern times, lime plaster has been a reliable choice for building and restoration. A comparison of lime plaster with other skim coating materials, such as gypsum plaster, cement plaster, and clay plaster, highlights significant differences in properties and applications that are critical for renovation projects.

A comparison of lime plaster with other skim coating materials, such as gypsum plaster, cement plaster, and clay plaster, highlights significant differences in properties and applications that are critical for renovation projects.

Lime plaster is particularly notable for its breathability and capacity to manage moisture, qualities that are frequently absent in contemporary materials like cement plaster, which may trap moisture and contribute to damp issues.

Lime Plaster Vs. Gypsum Plaster

When comparing lime plaster to gypsum plaster, the primary distinction is found in their moisture management capabilities. Lime plaster is breathable, effectively mitigating damp issues, whereas gypsum plaster has a tendency to trap moisture, which may lead to deterioration over time. This characteristic renders lime plaster a more appropriate choice for renovation projects involving historic properties, where careful moisture considerations are paramount. Thistle is a well-known brand for Gypsum plasters, often used in modern construction.

Plus its moisture management properties, and the versatility of lime plaster in application is noteworthy. Unlike gypsum plaster, which is generally confined to internal use due to its susceptibility to damage from water exposure, lime plaster can be employed in a variety of environments, including external applications, due to its durable composition.

The following are key differences between the two materials, often highlighted by the ASBP (Alliance for Sustainable Building Products):

- Properties: Lime plaster is flexible and capable of accommodating structural movement, whereas gypsum plaster is rigid and may be prone to cracking.

- Environmental Suitability: Lime plaster is well-suited for humid and damp conditions, while gypsum plaster is typically recommended for dry internal settings.

- Setting Time: Lime plaster requires a longer setting time, which can be advantageous for intricate applications, in contrast to the rapid setting nature of gypsum plaster.

These factors significantly inform the decision-making process when selecting the appropriate plaster type for specific construction or restoration projects.

Lime Plaster Vs. Cement Plaster

Lime Plaster, especially Natural Hydraulic Lime and Non Hydraulic Lime, offers benefits that are superior to cement plaster in terms of flexibility and sustainability. Historically used in Cottage and Farm buildings, lime plaster provides a breathable and eco-friendly alternative to cement.

A comparison between lime plaster and cement plaster reveals significant differences in their moisture management capabilities. Lime plaster is breathable, facilitating the evaporation of moisture, whereas cement plaster can retain moisture, which may lead to structural complications over time. This characteristic of breathability positions lime plaster as the preferred material for renovation projects in historically significant buildings.

Additionally, the differences in durability between the two materials are noteworthy. Lime plaster not only offers flexibility, which aids in preventing cracking, but it also tends to age gracefully, preserving its aesthetic appeal. Conversely, cement plaster provides superior strength and is less vulnerable to degradation from external factors. However, its rigidity often results in cracking over time, particularly in older structures that undergo movement.

The following is a brief overview of the advantages and disadvantages of each material in the context of renovation:

- Lime Plaster:

- Advantages: Breathability, flexibility, eco-friendliness, aesthetic appeal.

- Disadvantages: Requires skilled application, longer drying time.

- Cement Plaster:

- Advantages: High durability, quick application, moisture resistance.

- Disadvantages: Non-breathable, potential for structural issues over time.

Lime Plaster Vs. Clay Plaster

When comparing lime plaster to clay plaster, it is evident that both materials provide breathability and possess natural properties. However, lime plaster is generally regarded as more durable and moisture-resistant, making it a more practical choice for renovation projects in environments susceptible to dampness.

The advantages of lime plaster, particularly its moisture resistance, are particularly relevant in areas characterised by high humidity or significant water exposure, such as those found in the historical cottages of the UK or regions like Italy. This property allows structures to maintain a stable internal environment by effectively wicking away moisture, thereby preventing long-term damage.

On the other hand, clay plaster, often compared with materials like Gypsum, is an excellent choice for interior spaces where aesthetics hold particular importance, as it imparts a unique texture that can enhance the visual appeal of any room.

- Durability: Lime plaster typically outperforms clay plaster in terms of longevity, making it a prudent investment for renovation projects.

- Aesthetics: Clay plaster offers a distinct artistic appearance, appealing to those seeking an organic touch in their interiors.

- Maintenance: While lime plaster generally requires less maintenance, clay plaster often demands more frequent monitoring and repair, particularly in fluctuating climates.

Ultimately, the decision between these materials should be guided by the specific environmental conditions and desired aesthetic outcomes of the renovation project.